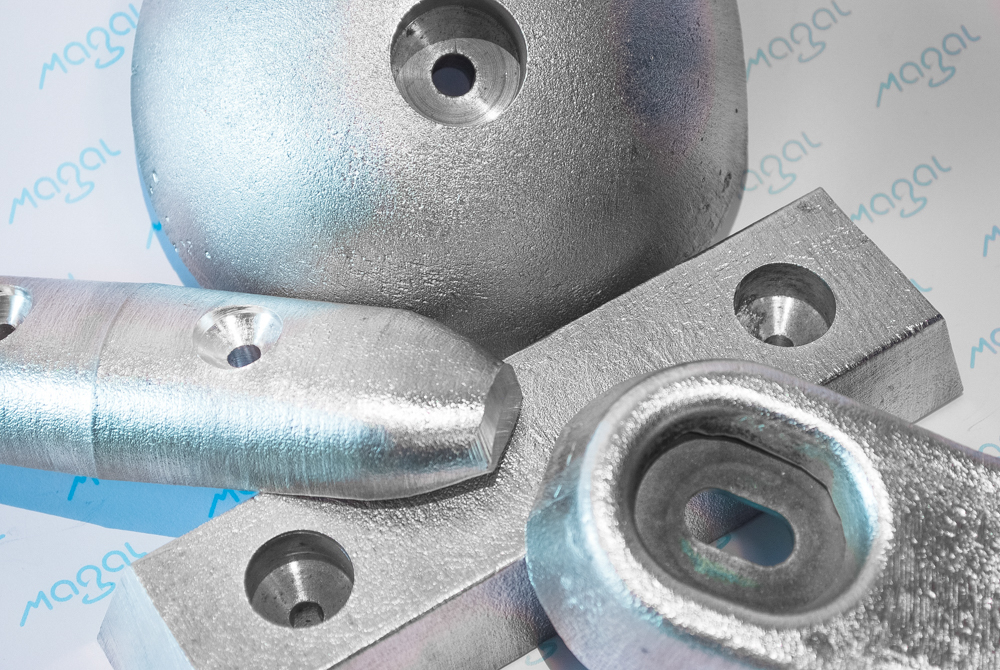

Anodes for vessels

Corrosion represents the unwanted destruction of materials resulting from the complex physical-chemical and electrochemical effect of the surrounding environment. The word corrosion comes from the Latin word ” corrodere ” which means “to eat into”.

Metal corrosion is an inverted process of obtaining metals, and it represents a natural occurrence of the return of metals to an initial equilibrium state, with the system reducing free energy. As a result of this process, a gradual and often sudden loss of the basic function of the elements of the system or system as a whole occurs.

By reducing corrosion with protection, the possibility of losing various products is reduced, and thus increasing their economy. Protection of metals and corrosion alloys can be achieved by using a number of methods that include: material selection, structural solutions, protective coatings, inhibitors, electrochemical cathodic protection and passivation.

Our long experience in the production of galvanic anodes ensures that you will get top quality anodes that will effectively inhibit corrosion when used in a properly designed and maintained cathodic protection system.

Electrochemical cathodic protection against corrosion is carried out for those metals and alloys that are not readily available for maintenance and cannot be easily maintained, proteced by other methods of protection. Electrochemical corrosion protection is used in the protection of reservoirs, water treatment vessels, boats and various vessels, pipelines, oil pipelines and many other devices and constructions used in industry.

One type of cathodic protection system is the protection of the sacrificial anode. Losing or sacrificing an anode material leads to the alternative name of the sacrificial anode.

The advantage of sacrificial anode systems, protectors in relation to other systems of electrochemical cathodic protection is that they do not need an external power source, are easy to install, low voltage and current between the anode and the surface we protect, excessive protection is unlikely, and control and supervision are simple.

Anode is made of metallic alloy with more active voltage (more negative electrochemical potential) than metal structure that needs to be protected. (cathode).The difference in the potential between the two metals means that the sacrificial anode is corroded and consumed, effectively stopping the oxidation reaction to the structure we protect

When the sacrificial anode and the system we protect are found in the electroconductive environment (electrolyte), then a galvanic element (pair) is formed. In doing so, two main reactions are formed on one anode, the other on the cathode (a system we are protecting). Anodic reactions are always oxidation and they lead to the formation of an ion-oxide, oxide or hydroxide metal in the electrolyte. It is said that the anode is corroded or oxidized, which is manifested by the loss of metal, while on the cathode there are reduction reactions that have less effect on the metal cathode, because in most cases it is already sufficiently reduced.

Metals that are most commonly used for the application of sacrificial anodes, galvanic anodes are magnesium, aluminum and zinc. Magnesium has the best characteristics for use as sacrificial, galvanic anodes because it has a lower standard potential compared to aluminum and zinc.

For these reasons magnesium has found a wide application in the protection of reservoirs, especially hot water containers, underground pipelines, ships and various vessels, metal structures and other devices used in industry.